Enva expands recycled compound range

30 Oct 2020

The new high melt compounds enable customers to realise significant production improvements and environmental benefits.

Enva has expanded its range of recycled plastic compounds range with the introduction of a new suite of high melt Polypropylene (PP) products.

With Melt Flow Rates (MFR) of 15, 25, 35 and 45 these new polymers offer injection moulders a number of production benefits, increasing productivity and product quality. These include:

- Improved processing characteristics, especially through hot runner and pin gate systems. This results in less flow marks on the moulding.

- Faster crystallinity and quicker cooling times leading to reduced cycle times and increased capacity

- Better definition products, especially those with intricate mouldings.

- Enhanced aesthetics

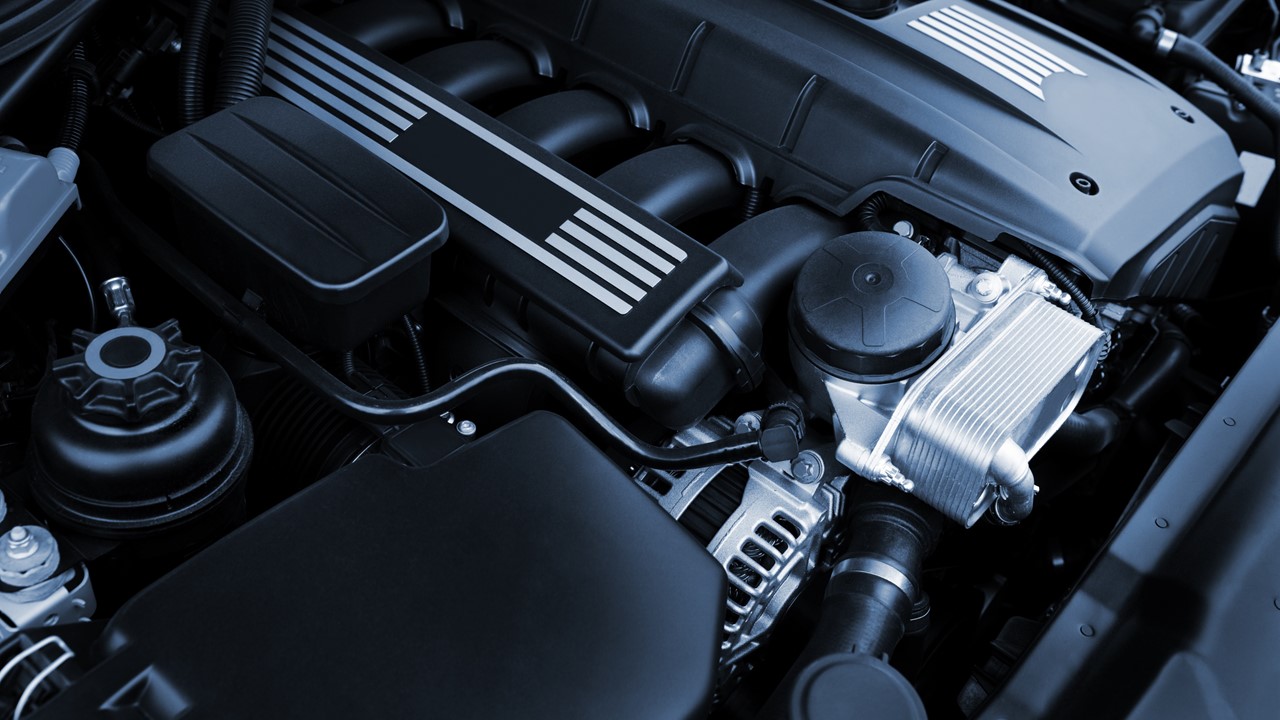

The quality of recycled polymers is now wholly comparable to those from virgin sources. As a result, customers can realise their environmental benefits and cost savings without having to compromise on product quality. The use of waste rigid plastics in the production of these recycled polymers provides a fully circular solution for those manufacturing products for a range of industries such as automotive, construction or horticulture.

For more information please contact our Compound Sales Manager Chris Cutts.

Email - Chris.Cutts@enva.com

Phone - +44 (0)7593 507932

Read more Plastic recycling process | Recycled plastic compounds | Injection Moulding polymers

| View all stories